Selection Guide

Selection Guide

Chain Conveyor Applications

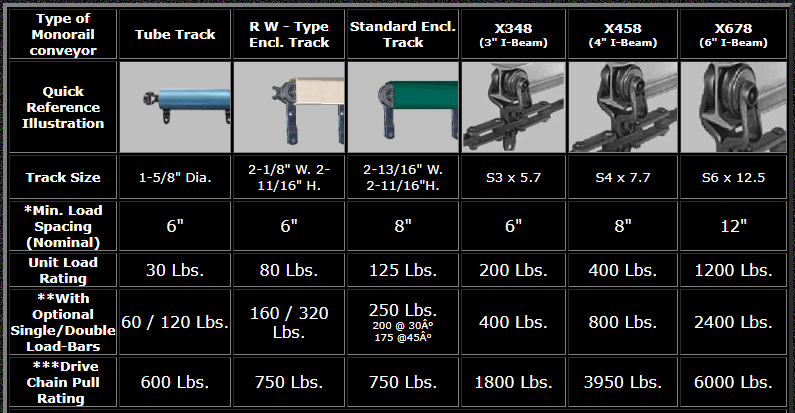

Determine which type overhead conveyor best suits your application using this chart, depending on maximum unit load, part spacing and chain pull requirement.

Also scroll down to "cost comparison" for specifications and relative equipment costs.

Need further assistance? Feel free to give us a call. We would be pleased to discuss your application.

*The minimum load spacing is also the nominal chain pitch for each type system. Loads may be spaced on any increment of this chain pitch, depending on your requirement and any additional clearance needed for your product to maneuver the selected turns and vertical curves. Larger radius turns require less clearance.

**Increase capacity by use of load-bars, but keep in mind it is often less expensive to go to the larger conveyor, unless they are spaced far apart.

***A quick idea on your drive pull requirement may be determined by multiplying the total live load by .035 (monoplane systems only). Elevation changes add "lift pull" to your total. Lift pull is calculated by multiplying the total elevation change of inclines only (no declines) by the product weight per foot of conveyor.

Note: Should this method result in any more than half of the rated system capacity, give us a call to consider your chain pull more closely. Adequate drive pull capacity is an important factor in your decision. Save by selecting the correct drive arrangement up front, rather than making corrections later.

Cost Comparison for Chain Conveyor Applications

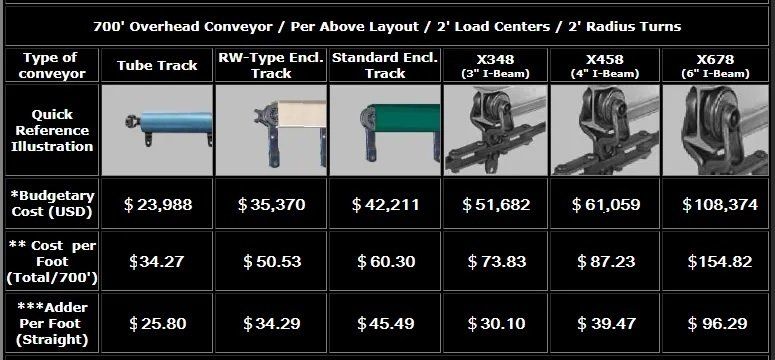

See the following sample layout and budgetary price chart for relative costs of available equipment. Actual cost may vary depending on the application and customer discount.

Sample Layout - Overhead Paint Line Conveyor

Budgetary Price Chart

*

Includes required chain, trolleys, track, turns, vertical curves, attachments, drive, take-up and lubricator for the above layout. Price is reference only. Call now for discount price per your specific needs.

**

Average cost per foot is based on this example and varies with changes in system length due to certain fixed costs such as curves, drive, take-up & lubricator.

***

Add or subtract this cost per foot from the above budget price if your layout is similar but longer or shorter than the 700' system example shown here. This price per foot includes parts needed for straight runs only with attachments on 2' centers.

PAGES YOU LIKE

CONTACT US

1549 Pirtle Drive

P.O. Box 246,

Georgetown, IN 47122

Martin Gregory Conveyor and Engineering Company, LLC. All rights reserved

© 2024